GF-series structural aluminum frames have been designed as a material for workstations, trolleys, chutes, and racks, to offer the optimum adaptability to factory automation. Its unique sectional form is most suited for simple and fast assemblies and modifications with use of a single bolt; this offers the maximum flexibility to unexpected additions and layout changes frequently required in manufacturing sites. The lightweight aluminum frame, with elegant alumite treatment, will help you maintain aesthetic appearance of the factory for long. What's more, the aluminum is an excellent material for recycling and reuse. Perfect freedom to choose the best combination of frames and accessories allows for a customized system that will satisfy your needs.

It's lighter than existing iron, plastic or composite pipe and has excellent recyclability because Green Frame adopts aluminum extrusion.

It's easy to disassemble and also reusable because all of the connectors can be combined by bolt. In order to improve the recyclability, we adopted aluminum material for connector, too.

Because connector is combined by one bolt nut, assembly procedure is reduced, and contributes to save customer's power

For aluminum reclamation, about 3/100 energy of manufacturing new bare metal is needed. We can reduce consumption of natural source "bauxite".

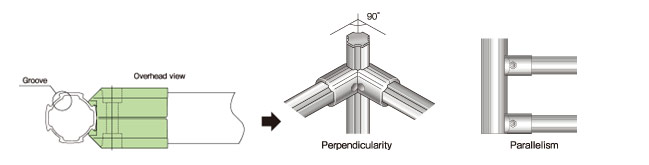

The frame is equipped with a pair of grooves in each of the four directions. A connector can fit in the grooves with use of a single bolt. Degree of perpendicularity and parallelism is apparent with use of grooves facing the four directions.

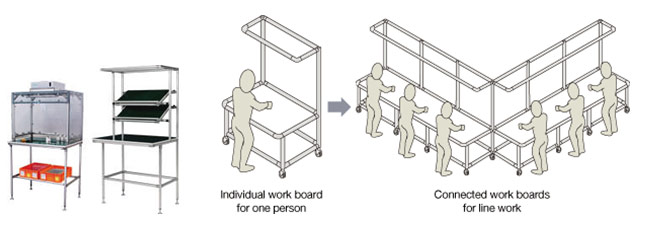

Workstation combination can flexibly be modified according to working space and staffing conditions of a cell production system. Individual workstations can easily be connected for line works, and vice versa.