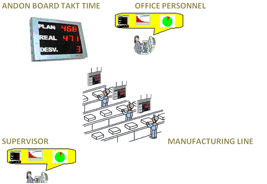

At Andon Technologies we are manufacturers and we have a standard line of Andon systems. From traditional hard wire Andon Board lights, to wireless PC communication which keeps exact statistics for each of the problems on the line and visually display them to the team members. Also keeps executives informed in real time from any remote office computer. We also customize systems according to customer needs

Taiicho Onho one of the creators of the Toyota Production System or Just in Time, said once: “An assembly line that never turns its Andon board is perfect (which is impossible of course) or is a very bad assembly line”. In manufacturing problems will always occur and its early identification is key to build a quality product.

A delay can make it difficult to identify the cause of the problem and in many cases no longer be identified. Time destroys the evidence and it is very difficult to find the causes, the best time to analyze the causes of the problems is when they are still active. In conventional manufacturing, no vary records the real causes of a problem. Then the workers have the eerie feeling that they are blamed for most of the problems. Shining a light or a sound on the Andon system gives people the opportunity to explain the real causes as soon as it happen, so you do not have to guess or rely on memory problems.